RESOURCES FOR USERS

Put the ease in grease

High-Performance Multiuse Grease

If a certified HPM grease is appropriate for broader set of applications, it may reduce the number of greases needed in inventory, so inventory can be better managed and there is less opportunity to grab wrong grease out of the stock.

The goal of the HPM Grease program is to provide a level of confidence in selecting the right grease for applications where a high-performance grease is required.

How to Identify Certified HPM Greases

The High-Performance Multiuse (HPM) Grease Certification Program is designed for greases used in various lubricating applications. Although not suitable for all applications, NLGI’s HPM grease specification is designed to ensure a high level of performance for many different applications (multiuse), such as the following:

Conveyor Bearings • Hinges • Electric Motor Bearings • Ball Screws • Pillow Block Fan Bearings • Rollers • Thrust Bearings • Rolling Element Bearings • Industrial Gearbox Bearings • Presses • Pump Bearings • Plain Bearings • Winches • Bushings • Linear Bearings

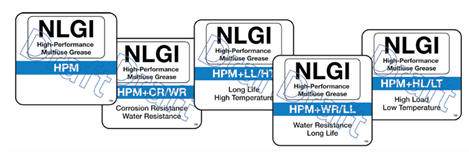

The HPM certification and enhanced performance tags above allow grease users to easily identify and understand that products have passed the proven performance testing required by the program.

The HPM Core specification offers additional performance through sub-categories such as:

The HPM+WR Specification includes tests intended to demonstrate an increased level of performance over the HPM core Specification in wet or water wash environments.

The HPM+CR Specification includes tests intended to demonstrate improved corrosion resistance over the HPM core Specification in saltwater environments.

The HPM+HL Specification includes tests intended to demonstrate improved load carrying capability over the HPM core Specification.

The HPM+LT Specification includes tests intended to demonstrate improved low temperature performance over the HPM core Specification.

Specification Testing Explained

For applications that involve shearing of the grease, the ASTM D217 10,000 or 100,000 multi-stroke penetration tests and the ASTM D1831 Roll Stability Test provide an indication of how the grease will hold up under shear conditions.

In cases where water resistance is important to the grease performance, ASTM D1264 Water Washout and ASTM D4049 Water Spray-off may indicate how the grease will perform. In addition, ASTM D8022 Roll Stability in the Presence of Water gives an indication of how the grease performs under both wet and shear conditions.

For those applications where resistance to corrosion is important ASTM D4048 Copper Corrosion, ASTM D1743 Corrosion Prevention, and ASTM D6138 Dynamic Corrosion Resistance (Emcor) offer insight to grease performance. For more extreme conditions, ASTM D5969 Synthetic Sea Water Corrosion Prevention and ASTM D6138 using 100% Synthetic Sea Water or 0.5 N sodium chloride (NaCl) solution can be used.

When a grease will be exposed to high loads and must prevent wear under highly loaded conditions, D2266 Wear Prevention (Four-Ball Method) and D2596 Extreme Pressure Properties (Four-Ball Method) are used to indicate performance in those properties. Additional tests, D5706 Extreme Pressure Properties Using the SRV Test Machine and Fretting Wear Resistance by either D4170 Fretting Wear Protection or D7594 Fretting Wear Resistance Using an SRV Machine can be used when more extreme or specific types of operating conditions are to be encountered.

When a grease is to be exposed to low temperatures, the D1478 Low-Temperature Ball Bearing Torque Test is used to indicate how the grease will perform. The test temperature can be lowered to test how the grease will perform in more extreme conditions. Other tests, the DIN 51805 Flow Pressure Test and the US Steel Grease Mobility Test, can be added to provide an indication of the flow and handling characteristics of the grease at low temperatures.

Stay up-to-date on HPM Certified Grease products

There are many ways to stay up-to-date with latest information regarding HPM Certified Grease products, articles, tips, and more.

- Subscribe to get periodic updates

- Visit our News section

- Follow us on LinkedIn